The automotive industry is a symphony of interconnected components, each playing a critical role in a vehicle's performance, safety, and efficiency. Among these, plain carbon Electric Resistance Welding (ERW) tubes often operate as an unseen but vital backbone. These tubes, made from a flat strip of steel cold-formed into a cylinder and then welded along its length using electrical resistance, are integral to a vast array of automotive applications, from structural elements to fluid transportation. Understanding the dynamics of this market is crucial for stakeholders across the automotive value chain.

Automotive plain carbon electric resistance welding (ERW) tubes market is expected to gain market growth in the forecast period of 2022 to 2029. Data Bridge Market Research analyses the market to grow at a CAGR of 5.00% in the above-mentioned forecast period.

Access Full 350 Pages PDF Report @

Introduction to Automotive Plain Carbon ERW Tubes

Plain carbon ERW tubes are essentially steel tubes characterized by their excellent formability, weldability, and cost-effectiveness. Their manufacturing process, involving precise welding without the addition of filler material, ensures high dimensional accuracy and consistent mechanical properties. In the automotive sector, these tubes are indispensable in various critical applications. They contribute to steering linkages, steering columns, shock absorbers, propeller shafts, tie rods, body frames, rear body frames, and axle tubes. Their ability to deliver a favorable strength-to-weight ratio is particularly attractive in an industry constantly striving for lighter vehicles and improved fuel efficiency.

Market Size and Growth

The global market for automotive plain carbon ERW tubes is a significant segment within the broader steel tubes and welded pipes industries. In 2024, the automotive plain carbon ERW tubes market size was estimated to be around USD 6.06 billion. Projections indicate a robust growth trajectory, with the market expected to reach USD 9.23 billion by 2034, reflecting a Compound Annual Growth Rate (CAGR) of over 4.3% between 2025 and 2034. This growth is intrinsically linked to the overall expansion of the global automotive industry and the increasing demand for high-quality, cost-effective components. The wider Electric Resistance Welded (ERW) Pipes and Tubes market was valued at approximately USD 80 billion in 2023 and is projected to grow to around USD 115 billion by 2032, at a CAGR of 4.1%. This further highlights the substantial contribution of ERW technology to industrial applications, with automotive being a leading segment.

Market Share Dynamics

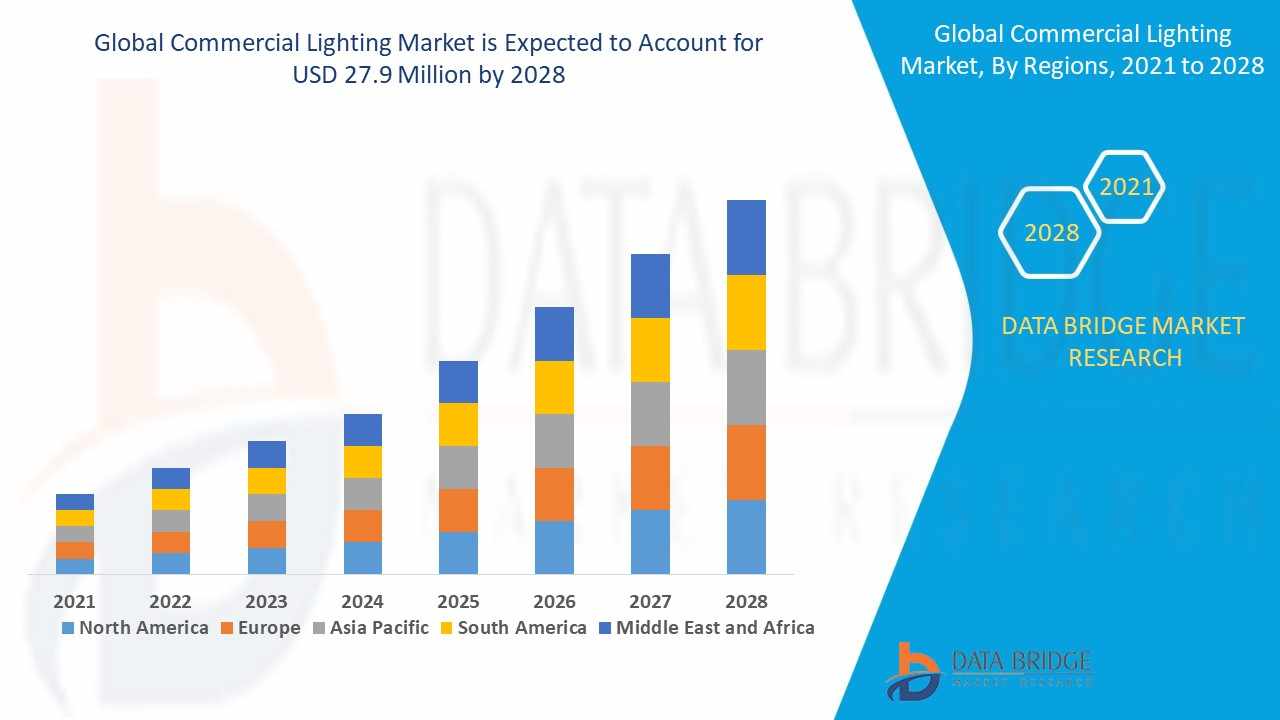

In terms of market share, the automotive segment held the largest share of the overall welded steel tubes market in 2024, and the ERW segment itself held the largest share of the total welded steel tube market. Within the automotive plain carbon ERW tubes market specifically, Asia-Pacific emerged as the dominant region in previous years, capturing a significant share due to strong automotive production in countries like China, India, Japan, and South Korea. This dominance is expected to continue, driven by rapid industrialization and infrastructure development. Europe and North America also hold substantial market shares, with established automotive industries and a focus on advanced manufacturing techniques.

Regarding application, frames have historically exhibited the largest market size within the automotive plain carbon ERW tubes market, accounting for a substantial share. This is due to their fundamental role in vehicle structure and integrity, with demand driven by the need for lightweight and high-strength materials. Passenger cars also constitute a dominant segment by vehicle type, commanding a significant share of the market.

Market Opportunities and Challenges

The automotive plain carbon ERW tubes market presents a compelling set of opportunities and challenges.

Opportunities:

Lightweighting Initiatives: The automotive industry's continuous pursuit of fuel efficiency and reduced emissions drives the demand for lightweight materials. Plain carbon ERW tubes, with their favorable strength-to-weight ratio, offer a cost-effective solution for weight reduction in chassis frames, suspensions, and other components.

Rise of Electric Vehicles (EVs): The booming EV market presents a significant opportunity. ERW tubes are crucial components in EV battery packs, chassis structures, and cooling systems, contributing to extended battery range and overall vehicle efficiency.

Technological Advancements: Ongoing improvements in ERW welding technology are leading to higher quality, more precise tubes with superior mechanical properties. Advanced automation and robotics are enhancing production efficiency and capacity, further optimizing the manufacturing process.

Growth in Emerging Markets: Rapid growth in vehicle production in developing economies, particularly in the Asia-Pacific region, creates substantial demand for ERW tubes. This represents a large, untapped market potential for manufacturers.

Advanced Driver-Assistance Systems (ADAS): The increasing adoption of ADAS systems also fuels market expansion, as ERW tubes are crucial for various structural and protective elements associated with these technologies.

Challenges:

Volatility of Raw Material Prices: Fluctuations in the prices of raw materials, primarily steel, pose a significant challenge. These fluctuations can directly impact production costs and profit margins for manufacturers, making strategic procurement and hedging crucial.

Competition from Alternative Materials: The increasing focus on alternative materials such as aluminum and composite materials for automotive applications may limit the market potential for plain carbon ERW tubes. While ERW tubes offer distinct advantages, the industry's material evolution necessitates continuous innovation.

Stringent Regulatory Standards: Evolving and stringent regulatory standards regarding emissions and vehicle safety can lead to increased compliance costs for manufacturers. Meeting these regulations may necessitate investment in research and development to produce tubes that adhere to new requirements.

Intense Competition: The market is characterized by a moderately concentrated landscape with several major players. Intense competition from both established manufacturers and new entrants requires continuous innovation and strategic differentiation.

Market Demand

The demand for automotive plain carbon ERW tubes is directly correlated with global vehicle production volumes and the evolving design and engineering requirements of the automotive industry. The relentless pursuit of fuel efficiency, safety enhancements, and reduced emissions drives the demand for high-strength, lightweight, and durable tubing solutions. The increasing adoption of precision steel tubes in components like fuel injection, airbags, and hydraulic and exhaust systems further contributes to this demand. As the global automotive industry continues to expand, particularly with the surge in EV manufacturing and the increasing sophistication of vehicle components, the demand for ERW tubes is projected to remain strong.

Market Trends

Several key trends are shaping the automotive plain carbon ERW tubes market:

Focus on Lightweighting: This remains a paramount trend. Manufacturers are continuously exploring ways to reduce vehicle weight to improve fuel economy and reduce carbon emissions. ERW tubes, with their ability to offer high strength with less material, are well-positioned to benefit from this trend.

Electrification of Vehicles: The rapid shift towards electric and hybrid vehicles is a major driver. ERW tubes are critical for battery cooling systems, structural elements in battery packs, and lighter chassis designs in EVs.

Advanced Manufacturing Technologies: The adoption of advanced welding technologies, automation, and robotics in tube manufacturing is a growing trend. These technologies enhance precision, reduce defects, improve production efficiency, and contribute to higher quality tubes.

Customization and Specialization: There's a growing demand for customized ERW tube solutions tailored to specific automotive applications. This includes tubes with precise dimensions, specialized coatings for corrosion resistance, and enhanced mechanical properties to meet stringent performance requirements.

Sustainability and Circular Economy: A rising emphasis on sustainable manufacturing practices and the circular economy is influencing the market. Manufacturers are exploring ways to reduce waste, optimize material usage, and enhance the recyclability of ERW tubes.

Emerging Markets as Growth Hubs: Asia-Pacific continues to be a primary growth engine for the automotive plain carbon ERW tubes market due to its robust automotive production and increasing demand for cost-effective and high-performance components.

In conclusion, the automotive plain carbon ERW tubes market is a dynamic and essential segment of the global automotive industry. Its growth is propelled by critical industry trends such as lightweighting and electrification. While challenges like raw material price volatility persist, continuous technological advancements and the increasing demand for high-performance, cost-effective solutions promise a robust future for this vital automotive component.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Write a comment ...